Carlos Raygoza

Data Engineer & Systems Analyst

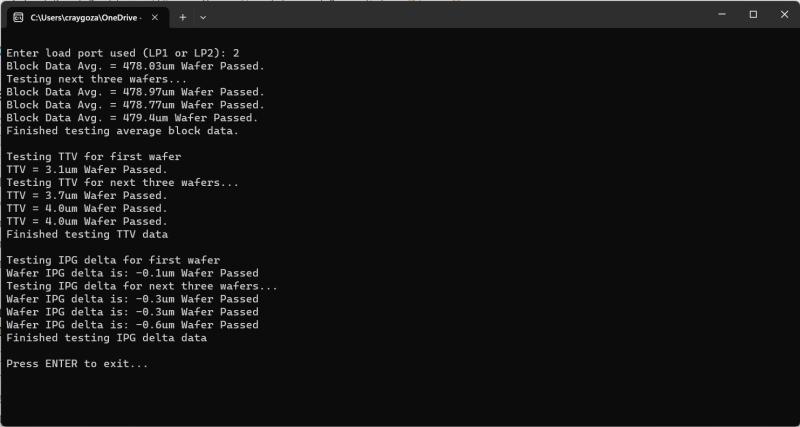

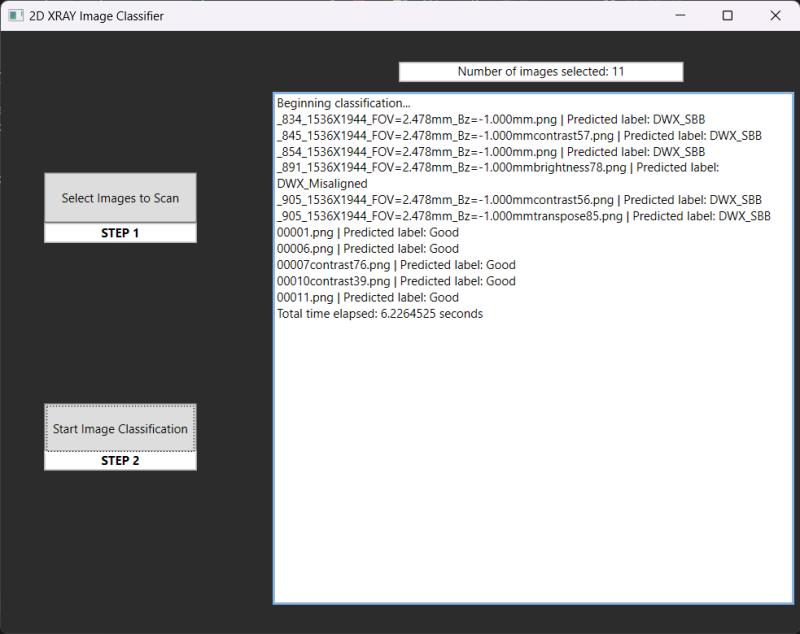

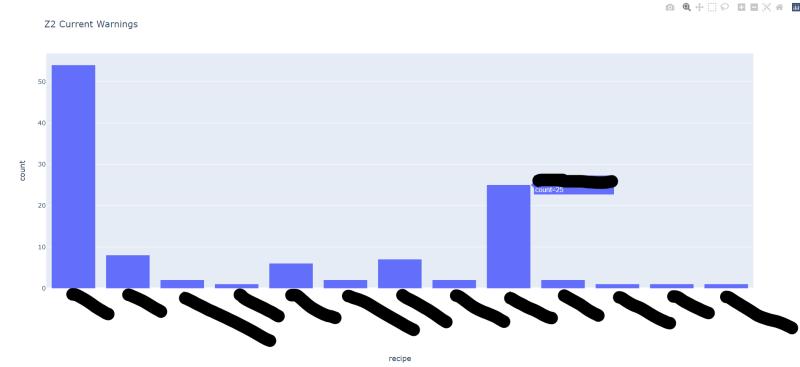

Technician-turned-data practitioner with 5+ years of hands-on experience building data pipelines, automating manufacturing analytics, and prototyping AI/ML solutions. Expertise in bridging hardware systems with scalable data tools, from semiconductor equipment maintenance to production-ready automation workflows. Proven ability to transform manual processes, apply computer vision to real-world problems, and deliver data-driven insights across cross-functional teams.